Demand-driven Design

First, through demand analysis, clarify the functions, specifications, and environmental adaptability (such as indoor/outdoor, corrosive/dust-prone environments), and draw detailed drawings including the cabinet structure, component layout, and wiring direction. After review and confirmation, these will be transformed into production documents. For example, in high-humidity environments, the installation position of the moisture-proof heater needs to be planned in advance, and in explosive environments, a dust-proof cavity and cavity need to be reserved.

Material Selection and Acceptance

Metal Base Materials: For ordinary environments, select cold-rolled steel (yield strength ≥ 345 MPa); for coastal/chemical areas, use 316L stainless steel (molybdenum content ≥ 2%, salt spray life up to 5000 hours); for lightweight requirements, select aluminum alloy.

Insulation Materials: Prefer epoxy resin or polytetrafluoroethylene to ensure no leakage risk in humid heat environments.

Supplementary Materials: Sealant selects aged-resistant silicone rubber, coating uses polytetrafluoroethylene or outdoor-specific powder, all materials need to be qualified by quality inspection before being stored.

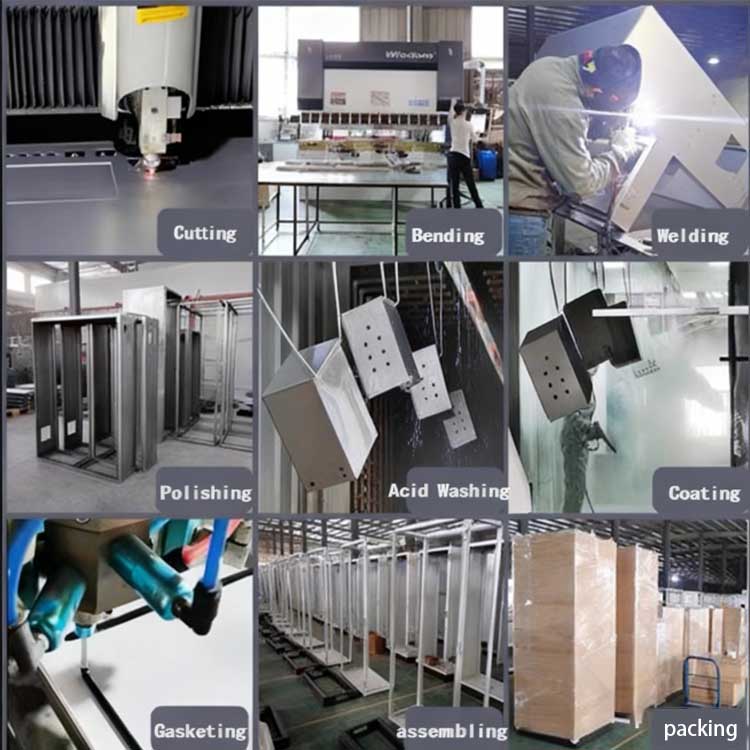

Precise Cutting

Cut metal sheets according to the drawing dimensions using a laser cutting machine (accuracy ±0.1mm). Simultaneously process complex holes (such as cable entry points, heat dissipation holes). The base plate should use 2.5~5mm thick steel plate to ensure stable component support.

Structural Bending and Punching

Use a bending machine combined with custom molds to bend the sheets into 90° cabinet corners or irregular structures. Thick plates (≥1.5mm) need to be pre-heated to avoid cracking; then, use a tower punch press to process installation holes, lock holes, and threaded holes. The threaded holes need to be made with tapping after welding.

Welding and Grinding

Cold-rolled steel and stainless steel cabinets are welded together using TIG welding to form a seamless frame structure, ensuring that any surface can withstand 100KG external force without deformation; after welding, use a grinding wheel to polish the weld seams to a smooth and flat finish, which not only avoids sharp edges causing injuries but also lays a foundation for subsequent coating treatment.

Pre-treatment Base Coat

Cold-rolled steel needs to undergo three steps of pre-treatment: degreasing (oil removal), acid washing (rust removal), and phosphating (forming an adhesion layer); stainless steel is treated with nitric acid to increase the chromium oxide film, enhancing corrosion resistance.

Coating Protection Upgrade

Cold-rolled steel: Electrostatically spray powder coating (thickness 60~120μm), which is cured at 180~220℃ to form a hard shell. In high-corrosion scenarios, additional Dacromet coating (salt spray ≥ 500 hours) can be added;

Aluminum Alloy: Use anodic oxidation treatment to form a 10~20μm thick oxide layer, which can be dyed and sealed to enhance weather resistance;

Special Scenarios: Explosion-proof cabinets are sprayed with fluorocarbon coating (thickness≥ 150μm), increasing the resistance to HCl acid fog erosion by 3 times.

Basic Components Installation

First, fix the cabinet frame connection parts, then install the grounding copper bar (arranged at the bottom side, with grounding labels attached), reinforcing hinges and locks; the edge of the cabinet door is pasted with double-layer silicone rubber sealant (compression≥3mm), ensuring the sealing performance meets the standard.

Component Layout and Wiring

Arrange components according to the electrical schematic diagram, avoiding electromagnetic and heat interference, and fix them on the base plate using screws and washers; wiring follows the "horizontal straight and vertical straight" principle, using wire clips and ties for fixation, and protecting important cables with protective sleeves, using dedicated copper connectors for pressing and ensuring secure connections.

Functional Components Installation

Protective Type: IP54 and above grades need to install detachable dust-proof nets; IP65 and above grades should be equipped with positive pressure ventilation systems (air pressure inside the cabinet > 50Pa);

Temperature Control Type: In high-humidity environments, add intelligent moisture-proof heaters (automatically start when humidity>70% RH); in high-temperature scenarios, install heat pipe cooling modules (thermal resistance≤0.5℃・m/W); Intelligent category: Integrates temperature and humidity sensors, as well as corrosive gas sensors, and links to the EcoStruxure platform to achieve real-time monitoring.

Basic performance testing

Appearance: Check for no scratches on the coating, no defects in welds, and ensure that components are securely installed without loosening;

Structure: Test the durability of the hinges after 5,000 opening and closing cycles of the cabinet door, and verify that the cabinet body does not deform under a 100N pressure;

Protection and safety testing

IP rating: IP65 requires 100kPa water pressure rinse for 30 minutes without leakage, and IP54 requires ensuring that the dust intrusion is less than 0.1%;

Electrical safety: Ground resistance≤0.1Ω, insulation resistance≥10MΩ(in high-humidity environments), explosion-proof models need to pass AS 3439 arc test;

Environmental verification: Conduct salt spray tests (5% NaCl solution for 96 hours without rust) and wet heat cycle tests (40°C/93% RH for 56 days without condensation);

Function debugging

Simulate actual working conditions to test control logic, and the intelligent cabinet needs to verify the sensor linkage and remote warning functions. All test data should be recorded and archived to form an inspection report.